Little Known Facts About Sheroz Earthworks.

Little Known Facts About Sheroz Earthworks.

Blog Article

Facts About Sheroz Earthworks Revealed

Table of ContentsSheroz Earthworks for DummiesSome Known Incorrect Statements About Sheroz Earthworks A Biased View of Sheroz EarthworksThe 7-Minute Rule for Sheroz EarthworksNot known Facts About Sheroz Earthworks

For any type of earthwork professional, it is important to carry out work with top quality, precision, and on schedule. Utilizing device control in job devices makes it possible for maximizing the different phases in the earthwork process, from intending to the maintenance phase - fj dynamics autosteer review. The device control system assists the machine driver in obtaining the target airplane quickly and quickly

The maker control system guides the driver with centimeter precision. Remote assistance conserves time and cash, as it decreases downtime in jobsites.

Everything about Sheroz Earthworks

Our system's elements are meticulously made to stand up to the harsh conditions of building and construction websites. Comparison of the exact same job carried out utilizing machine control versus the typical method exposes that, on average, the typical technique calls for 50% more time to accomplish the very same task as the technology-assisted technique.

Go into the Xsite machine control system; it's right here to give you with a considerable benefit when working with earthmoving machinery. Discover just how Xsite Machine Control can enhance your efficiency and make sure work safety and security! Xsite Machine Control systems can be installed to any type of excavator from mini excavators to huge mining excavators.

Just how does maker control job? In 2D systems, the device is furnished with adjusted inclination sensing units.

The system is really simple to discover the fundamentals can be instructed in under one hour of training. With Xsite you don't have to worry concerning learning all the pointers and method at the same time. Additional training and guidelines are constantly offered over remote support when needed. Get in touch with your regional Xsite supplier to figure out even more! Just how does the remote assistance job? A wireless internet link makes it possible to develop a remote link between the device control system and the service.

The 8-Minute Rule for Sheroz Earthworks

What sort of data layouts Xsite systems support? Xsite Device Control systems support open common file layouts, allowing seamless information circulation from one system to an additional. Sustained documents formats: 2D-Maps: DXF Point data: DXF, XML, GT, CSV, KOF, PXY Geometry lines: VGP, SBG, XML, Anpakke Surface Designs: DXF, XML What components are installed on my device? Relying on your choice of system (with or without positioning, i.e my latest blog post - trimble parts., 2D or 3D), your machine is geared up with disposition sensing units, a controller device, and a display/operating panel.

Lots of equipment and software application options exist to aid determine a maker's present position on the earth and contrast it with a wanted layout surfaceand construction drivers can do more to utilize the benefits. Maker control is the use of numerous placing sensing units and a screen to provide the driver with a recommendation in between the placement of the bucket or blade and the target grade.

Relying on the setup, machine control systems can give the driver with an easy visual guide to pail or blade placement, or can instantly relocate the blade to grade by speaking with the equipment's hydraulics - http://www.place123.net/place/sheroz-earthworks-brendale-australia. There are maker control systems readily available for just about any kind of equipment: graders, dozers, excavators, soil and asphalt compactors, scrapers, leaners, crushing devices, and pavers

The Best Strategy To Use For Sheroz Earthworks

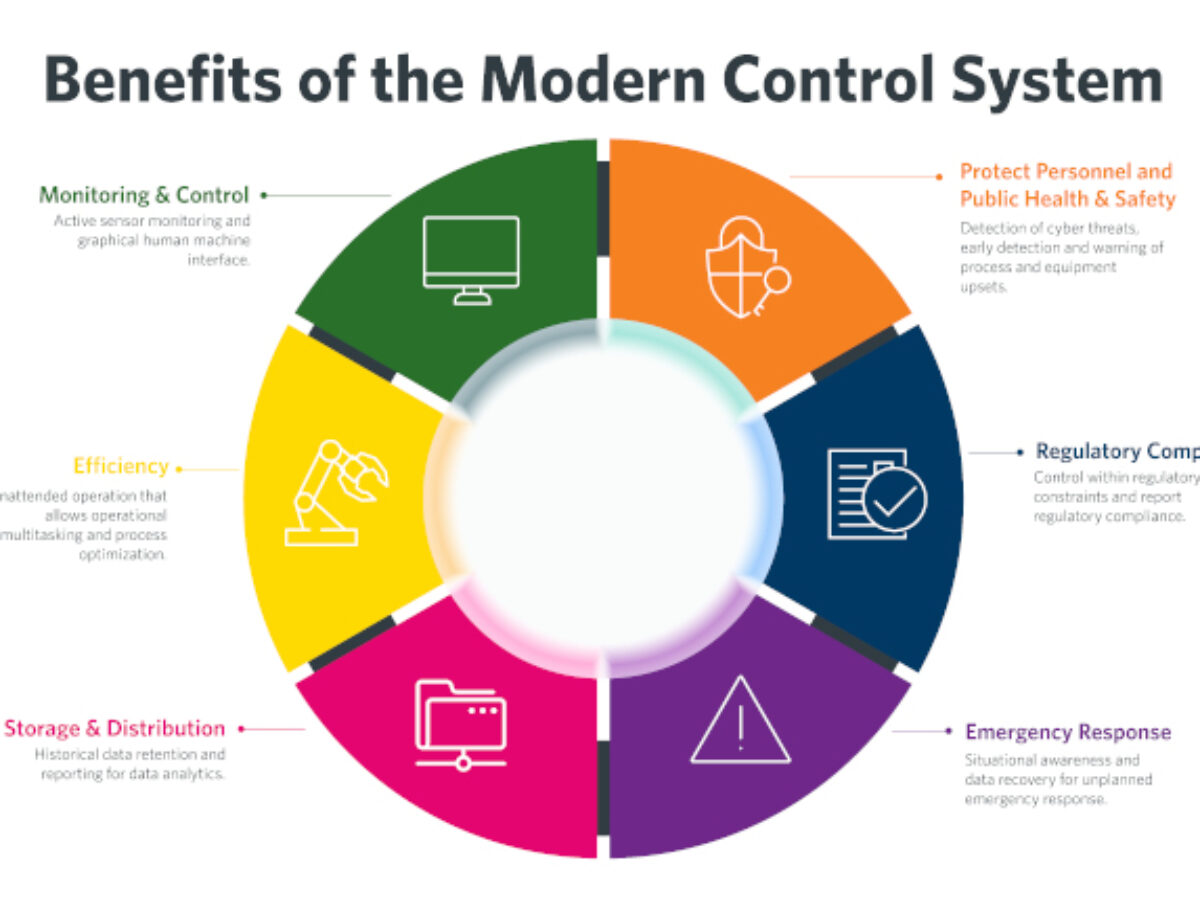

Some advantages include reduced rework, boosted job effectiveness, and lower checking prices. Device control can likewise help raise productivity and decrease general prices. This modern technology is altering the way the construction market functions. Building equipment without device control will certainly end up being a distant memory and the benefits got from it will be numerous.

Trimble equipment control systems offer a myriad of benefits to any person that utilizes earthwork equipment and, at EarthCalc, we can give you with 3D data for your machine control-enable equipment. Unsure if device control deserves the expense? Think about the complying with reasons why you require to consider this choice.

Using GPS straightened with your 3D style files, these systems virtually guarantee that you will get rid of or put the correct quantity of material at the building site. On a lot of building websites, rework is a common and frustrating truth, yet with Trimble maker control, you can remove the demand for rework.

Sheroz Earthworks - The Facts

Often, with Trimble equipment control, you can get rid of excess equipment at a specific task site. A job that may have needed the use of 3 or 4 items of digging deep into tools now might need just two items of tools to complete the same job in much less time. This enables you to move your tools to another task website and handle several work at once.

Report this page